How XR Technology is Reducing Waste in the Packaging Industry Through Improved Training and Operations

Introduction

The packaging industry has been grappling with sustainability challenges for years, including excessive waste and resource consumption. The total estimated waste in the packaging operations is estimated to be as high as 20%. However, with the advent of Extended Reality (XR) technology, there has been a paradigm shift towards sustainability through improved training and operations, resulting in reduced waste and increased efficiency.

XR Technology and Training in the Packaging Industry

One of the significant contributions of XR technology to sustainability in the packaging industry is in the realm of training. Traditionally, training in the packaging industry has relied on physical materials and in-person instructions, which can be time-consuming, costly, and prone to errors. With XR technology, packaging companies can provide virtual training experiences that are immersive, interactive, and efficient, leading to reduced mistakes and minimized waste during operations.

VR can be used to create realistic simulations of packaging processes, allowing workers to practice in a virtual environment before performing tasks in the physical world. This helps workers gain hands-on experience, learn from mistakes, and become proficient in their roles, reducing the likelihood of errors and waste during operations.

XR Technology Streamlining Packaging Operations

AR is also being used for on-the-job training in packaging operations. Workers can wear AR headsets or use AR-enabled devices to receive real-time instructions and guidance during packaging processes. AR overlays digital information onto the real-world environment, providing workers with visual cues, annotations, and feedback on their performance, leading to increased accuracy and efficiency. This helps workers complete tasks accurately and efficiently, minimizing mistakes that can result in waste or rework. AR can also be used for remote assistance, where experts can guide workers in real-time from a remote location, reducing the need for travel and associated carbon emissions.

Moreover, XR technology is being utilized to streamline packaging operations, leading to increased efficiency and reduced waste. For instance, AR can be used to optimize the layout of packaging materials and equipment on the assembly line, minimizing the time and effort needed to locate and transport items. This can reduce material waste, as workers can easily identify and access the right materials, tools, and machinery. AR can also be used to provide real-time feedback on the performance of packaging machines, helping operators make adjustments to optimize their operation and reduce errors.

Furthermore, XR technology is contributing to sustainability in the packaging industry by improving quality control and reducing defects. With AR and VR, inspectors can perform virtual inspections of packaging materials and products, identifying defects or inconsistencies without the need for physical handling or wasteful sampling. This helps catch defects early in the production process, reducing the number of defective products and the associated waste. In addition, AR can be used to overlay quality standards and guidelines onto the real-world environment, helping workers ensure that packaging materials meet the required specifications, reducing the chances of rework or waste due to non-compliant products.

Conclusion

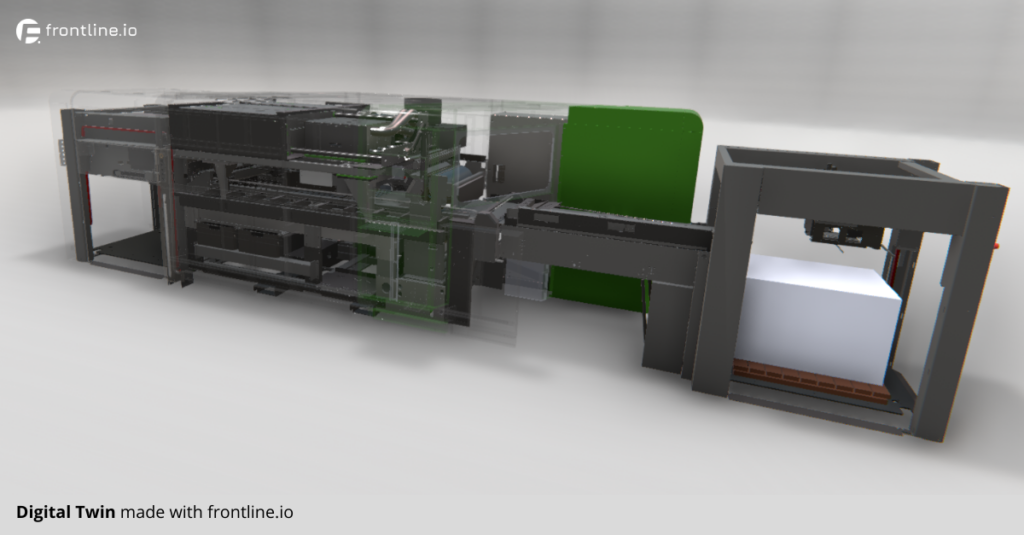

frontline.io is the most comprehensive platform for training and support leveraging XR technology, frontline.io customers are already enjoying reduced waste and improving their sustainability performances.

In conclusion, XR technology is playing a vital role in reducing waste in the packaging industry through improved training and operations. By providing immersive and efficient training experiences, optimizing packaging operations, improving quality control, and reducing mistakes, XR technology is helping packaging companies achieve higher levels of sustainability and efficiency. As the technology continues to advance, it is expected to have an even more significant impact on reducing waste and promoting sustainability in the packaging industry, contributing to a greener and more sustainable future.