The benefits of a machinery VR course

Advanced technology is now being utilized to enhance teaching, learning, development, efficiency, competence, and safety.

Virtual reality (VR), augmented reality (AR), and digital twin technologies provide significant prospects for automating manufacturing facilities, warehouses, and other supply chain elements.

The COVID-19 pandemic struck many manufacturing facilities severely, with continuing limitations to contain the virus making it difficult to bounce back. Some overhauled their operations with Internet of Things (IoT) devices that enabled monitoring a facility with fewer workers on site. Others invested in disinfection robots that travelled across warehouses to sterilize these premises between shifts.

Virtual reality (VR) has recently come to the forefront for helping manufacturers optimize their operations while keeping people safe during a global health risk. Since it can imitate real-life settings and scenarios in the digital arena, the technology allows manufacturing personnel to fully contribute to their duties, even away from physical facilities.

As manufacturers embrace innovation, workers can benefit from technical training and support powered by Digital Twin technology as part of an immersive machinery VR course.

What is a machinery VR course, and what are the benefits?

The digital simulation of lifelike settings for instruction is known as Virtual Reality Training (VRT). Workers are immersed in a 360-degree, interactive learning environment that blurs the line between virtual and real worlds. Workers can operate in a 3D virtual environment, converse with other virtual employees or teachers and move freely using the headset and controllers.

Source: https://aecmag.com/features/discussing-digital-twins/

Designing machinery VR courses with the use of a digital twin allows for:

- Training on the layout of the facility, the location of major equipment and identification of emergency gear

- Instrumentation, control and relief valves, and start-and-stop motors must be traced and located.

- Normal operations, including startup, shutdown, and faults.

- Sampling methods and rounds

- Lockout and tagout (LOTO) and the isolation of equipment.

The latest types of digital twin blend a 3D physical model of the plant with a mathematical model to teach workers in typical industrial settings better. In a secure, regulated, and efficient learning environment, this technology brings real-world plant experiences to life for workers.

While digital simulations are not a new phenomenon, a digital twin is different in that it updates in real-time. As the physical assets change, so does the digital twin, meaning machinery VR courses can work on genuine scenarios, giving workers more practical experience. Outputs are far more valuable and accurate.

Research by PriceWaterhouseCoopers shows that VR learning is four times more effective than typical classroom-style learning.

A VR Training Room ensures engagement with a Digital Twin to create an immersive machinery VR course. The VR remote training room demonstrates different scenarios that cannot always be shown on a physical machine, helping teams gain tacit knowledge through the Digital Twin. Interactive Flows and a Parts Catalog offer the full functionality of parts extraction, movement, hide, isolate and highlighting.

You’ll find plenty of intricate procedures, activities, and processes in the manufacturing industry. But at the same time, because of the high degree of standardization, it is also an extremely precise sphere. The VR Training Room for manufacturers allows workers to be trained in a shorter period, with lower costs, and in more suitable settings. Trainees can practice tasks and deal with various production-related mistakes to ensure they are ready to handle actual machinery.

Machinery VR courses ensure no materials are spent

Traditional onsite training necessitates manufacturers’ use of tangible materials to get their employees ready for the realities of production.

Using resources that can’t be recycled later in the production process incurs high costs. Manufacturing businesses dealing with high-end materials, such as composites in the aerospace sector, are particularly vulnerable to this issue.

In VR remote training, manufacturing processes don’t require actual materials and can considerably cut the costs connected with such resources compared to traditional methods. Simulated resources are used by users, while real-world resources are used for production.

A single source of truth

There is always a human aspect involved when engineers teach new employees.

The quality of learning depends on the educator’s technical competence and their ability to teach. The training experiences and outcomes of trainees might be vastly different between two teachers of the same ability.

The manufacturer’s expertise and best practices may be accessed in a single location using VR digital training.

Regardless of their technical background, each student receives the same in-depth instruction tailored to their individual needs. As a result of this uniformity, all new employees will have the same degree of professional expertise.

In addition to removing the human aspect in education, the capacity to swiftly update the training system is another benefit of a single knowledge repository.

A VR training system, for example, may quickly be updated without spending money on retraining teachers and personnel individually if new equipment is deployed or new compliance training methods are established.

Manufacturers are rarely in a single location. Relocating and translating training materials for a foreign staff consumes a significant amount of company resources.

A remote VR training environment may be accessible from any location and quickly customized to learn a new language. Manufacturers may save a large amount of money by using VR to create training divisions that operate in other cities or countries.

AR Remote Training

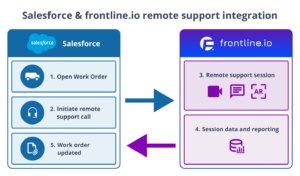

AR Remote Support can provide web sessions for users without downloading an application. It uses parts of the Digital Twin and Interactive Flows for real-time knowledge and support, requiring no pre-learning. The technician receives expert guidance through image capture and file sharing via live video chat.

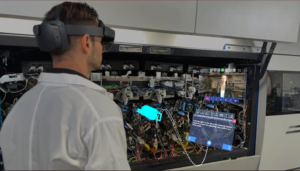

For example, a user can place a 3D model of an object on any surface to test different scenarios. They can rotate it, move it around and get granular information without inspecting the physical object. AR remote training finds the right person to assist no matter where they are, saving time and cost on providing ideal instructions for a typically tight budget manufacturing industry.

VR digital training use cases

As an example, virtual reality is the perfect technology for the aviation sector. It can be difficult for the next generation of aviation engineers to get hands-on experience since they must wait until specific complicated equipment is ready for practice. Engineers may not put their training to the test until an aircraft in need of repair comes up for maintenance.

It takes a lot of study time to repair expensive and complicated aeroplane elements like engines correctly.

A VR aircraft engine offers the opportunity to conduct a machinery VR course independently, regardless of machinery availability. For example, Rotax, a US manufacturer of jet engines, uses VR to train mechanics how to repair aircraft engines.

Engineers can peer inside and around engines using virtual experiences. In addition, they may use VR to explore almost any specific detail of the machinery.

Thanks to immersive technologies, training engineers to work with certain engine types and models considerably reduces cost and time.

Another example where VR remote training is advantageous comes with prototyping. In one example, a team that manufactures electric cars needed to test features for a new charging station. During the design stage, the VR environment allowed designers to inspect components and facilitate cross-sections to clarify where improvements were required. The process helps to eliminate typical trial and error approaches when handling physical equipment, reducing costs and mitigating any slow down in production time.

Summary

frontline.io is a platform created specifically to address manufacturing companies’ most pressing operational issues. The software can produce full digital twins with interactive 3D procedures, which reduce the footprint of field operations within days. Companies can provide remote virtual support without traditional bottlenecks and increase staff efficiencies by up to 60%.

By utilizing frontline.io our customers can create content once for VR/AR/MR PC and web

Contact frontline.io today for a demo of the Digital Twin model to understand how to create seamless, real-time experiences through the interactive platform.