Manufacturing is changing fast. Equipment is more complex, the workforce is shrinking, and traditional documentation simply cannot keep up. Today’s technicians expect interactive, digital learning, not long PDFs or classroom slides. This is exactly why manufacturers are turning to frontline.io, the AI-powered platform for training and real-time support.

In a recent episode of The Manufacturing Executive Podcast, Frontline.io COO Gilad Tzori joined host Joe Sullivan to explain how XR, Digital Twins, and AI-powered workflows are becoming the new foundation for operator training and real-time support. Here are the key takeaways and what they mean for modern manufacturing teams.

The Training Gap on Today’s Factory Floor

Traditional training was not built for today’s production environment. Classrooms, PDFs, and annual refreshers are too slow and too static. Tzori summarized the problem clearly:

“Machines are getting more and more complex and young people do not want to read PDFs anymore. The old training methods do not work.”

Manufacturers now face:

- Extreme product variability

- Loss of tribal knowledge as experts retire

- Higher service and training costs

- Increased pressure to onboard people quickly

This is why many training programs are falling behind.

Why Immersive Training Works Better

To engage today’s workforce, training needs to feel interactive, visual, and hands-on. “People do not have the energy to sit in a classroom and listen to boring PowerPoints. Training must move into the world of gaming,” said Tzori.

With an XR training platform like frontline.io, operators can:

- Practice on a realistic 3D Digital Twin

- Enter a virtual model of the machine

- Perform procedures safely at their own pace

- Learn on mobile, tablet, PC, AR, or VR

This results in faster onboarding and higher retention.

Collaborative Training for Distributed Teams

One of the most powerful ideas in the interview is multi-user, collaborative training. “Invite 10, 50, even 100 people into the same experience. Everyone has an avatar. One joins from mobile, another from PC, another with a VR or AR headset,” said Tzori.

frontline.io allows companies to create branded virtual training rooms where trainers and learners meet from anywhere. This eliminates travel, simplifies logistics, and reduces training center costs. Many organizations see training cost reductions of 50 percent or more. It also reduces carbon footprint by removing the need for travel and physical equipment.

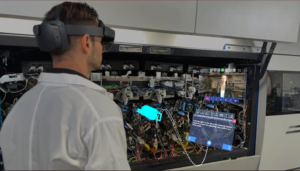

HP Shows What Scalable XR Training Looks Like

A practical example from the episode comes from HP Industrial Printing. “All their industrial printing machines are now using frontline.io for training. Technicians can put their head inside the machine and understand how it works,” said Tzori.

The impact is significant:

- Faster familiarity with complex machines

- Less time needed on the physical press

- Higher confidence during troubleshooting

- Hundreds of AR and VR devices deployed globally

Operators often request XR devices on the job because they instantly help them solve problems faster.

Accessible for Any Sized Manufacturer

While large enterprises deploy XR at scale, smaller companies can start small. “The solution can fit any size of company. Start with mobile or tablets. Start with 25 users and grow as you see the benefits,” said Tzori.

No major hardware investment is required. Companies simply begin with a focused use case, measure the value, and expand based on results.

AI Becomes the Real-Time Copilot

Tzori explains that AI is becoming a critical part of both training and support. It provides:

Guided troubleshooting

Technicians can ask: “I have a leak. Where is it coming from”

“The motor does not turn on. Take me step by step,” he said. AI routes them to the correct procedure immediately.

Converting PDFs into interactive procedures

Legacy documents are ingested and converted into modern, visual workflows.

Removing language barriers

Write once in English and deploy globally through instant translation.

Digital Twins That Know Each Machine Personally

Digital Twins are becoming fully personalized representations of each machine. They store history, usage, failures, and maintenance trends, giving operators the exact context they need. “You are not standing in front of one of many machines. This specific machine has its own history and its own needs,” said Tzori.

This leads to higher uptime, fewer errors, and faster decision-making on the floor.

What Comes Next: Lightweight AR, Always-On AI, Higher Uptime

Gilad predicts three key developments in the next few years:

- Lightweight AR and AI glasses that operators can wear all day

- Intelligent Digital Twins connected to every key asset

- AI copilots guiding technicians in real time

- This creates a simpler, safer, more accurate environment for training and support.

Listen to the Full Conversation

Hear the complete discussion with Frontline.io COO Gilad Tzori on The Manufacturing Executive Podcast.