Exploring the Power of 3D Parts Catalogs Based on Digital Twins Using AR and VR Technology

Introduction:

The industrial landscape is experiencing a remarkable transformation through the integrating of advanced technologies.

One such breakthrough innovation is the utilization of 3D parts catalogs based on Digital Twins, enhanced by the immersive capabilities of Augmented Reality (AR) and Virtual Reality (VR).

This cutting-edge combination is revolutionizing the way industries approach maintenance, repair, and operations, optimizing efficiency, accuracy, and productivity like never before.

The Existing parts catalogs face several challenges that hinder their effectiveness and limit their potential. These challenges include:

- Limited Visualization: Traditional parts catalogs often rely on 2D images or textual descriptions, making it difficult for users to visualize and understand the complex components and their interactions fully. This limitation can lead to errors, confusion, and inefficiencies during maintenance and repair tasks.

- Lack of Interactivity: Conventional parts catalogs lack interactivity, preventing users from interacting with the components and exploring their features in a dynamic

manner. Without the ability to manipulate virtual representations, technicians may struggle to grasp the intricacies of the parts or identify potential issues. - Difficulty in Contextual Understanding: Understanding the context in which a particular part fits into a larger system is crucial for efficient repairs. However, traditional parts catalogs often fail to provide this contextual information, making it challenging for technicians to determine the exact location, connections, and

dependencies of a specific component. - Inadequate Information Updates: Physical parts catalogs require frequent updates to incorporate new components, changes in specifications, or revised repair procedures. Ensuring that technicians have access to the most up-to-date information can be a cumbersome and time-consuming process, leading to outdated or inaccurate instructions.

- Limited Accessibility: Physical parts catalogs are often bulky and not easily accessible in remote locations or during on-site repairs. Technicians may face

difficulties in carrying and referencing these catalogs when working in challenging environments, hindering their efficiency and effectiveness. - Lack of Remote Support: Traditional parts catalogs do not offer built-in mechanisms for remote support. This absence makes it challenging for experts to provide real-time guidance to technicians who may be working in remote or challenging locations. As a result, issue resolution may be delayed, leading to increased downtime and costs.

- Training Limitations: Traditional parts catalogs may not provide comprehensive training resources for technicians. Learning complex assembly procedures solely through textual descriptions or static images can be challenging and may result in errors during actual repairs or maintenance.

Enhancing the Catalog Experience:

By integrating Digital Twins with AR and VR technology, 3D parts catalogs take interactivity and engagement to new heights. Users can visualize and manipulate virtual representations of components, assemblies, and machinery, gaining a comprehensive understanding of their functionality, connections, and relationships.

Digital Twin-Enabled 3D Parts Catalog:

A 3D parts catalog based on Digital Twins offers enhanced visualization, streamlined part allocation, and a direct connection between the model and the parts list. This innovative catalog can be accessed on various devices, including mobile, tablet, laptops, and PCs. By utilizing Digital Twins, the parts catalog establishes a direct link between components and procedures such as maintenance, troubleshooting, and parts replacements, providing a seamless and efficient experience.

Real-Time Visualization:

AR and VR technologies provide immersive experiences, allowing users to overlay digital content onto the physical world or dive into virtual environments. With 3D parts catalogs based on Digital Twins, users can access real-time visualizations, enabling them to identify issues, perform virtual tests, and troubleshoot problems in a risk-free, virtual setting. This capability drastically reduces downtime and enhances the accuracy of maintenance and repair procedures.

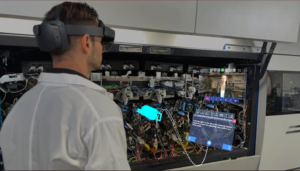

Remote Assistance and Collaboration:

One of the most significant advantages of AR-based 3D parts catalogs is the ability to provide remote assistance and collaboration. Technicians can leverage AR applications to receive guidance and support from experts who can virtually annotate and provide instructions directly on the physical equipment. This real-time collaboration minimizes travel costs, accelerates issue resolution, and empowers teams to work together seamlessly across geographical boundaries.

Training and Skill Development:

VR-based training modules within 3D parts catalogs offer an immersive and safe environment for hands-on learning. Employees can engage in realistic simulations, practice assembly procedures, and gain expertise without risking damage to physical assets. This approach enhances training efficiency, reduces training time, and improves the skill set of technicians, ultimately boosting operational effectiveness.

Conclusion:

The integration of 3D parts catalogs based on Digital Twins with AR and VR technology has unleashed a new era of efficiency and productivity within the industrial sector. Organizations can optimize maintenance, repair, and operations processes by harnessing the power of visualization, simulation, remote assistance, and immersive training, minimizing downtime, reducing costs, and maximizing asset performance. As industries continue to embrace these innovations, the future promises even greater advancements in industrial efficiency and effectiveness.