This article first appeared in Manufacturing Management, featuring an interview with frontline.io CEO Itzhak Pichadze.

Want to see how a digital twin works? Book a live demo of frontline.io

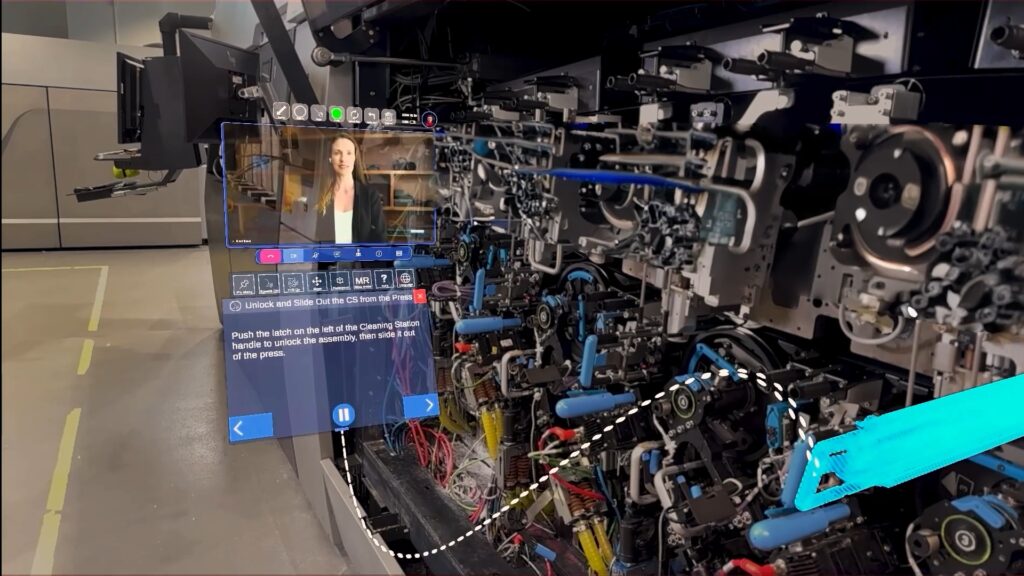

Online Editor Roshini Bains sits down with Itzhak Pichadze, CEO of frontline.io, a software platform that displays 3D machine models and offers clear, step-by-step instructions for maintenance, repair, and training

Sectors such as manufacturing and aerospace rely on large, complex machines, requiring skilled personnel for repair and maintenance. Training demands significant time, while ongoing maintenance increases service costs and creates variable support rates.

Itzhak Pichadze believes frontline.io offers a solution. The platform helps companies train staff, support field workers, and manage equipment using interactive 3D models and AR/VR technology. It converts large CAD or machine models into digital twins that can be manipulated, allowing technicians to follow interactive workflows instead of paper manuals, streamlining processes and improving efficiency.

From Repetitive Content to Zero-Code Management

frontline.io began as a services company, observing inefficiencies in sectors like defence, aerospace, and printing, where training and support content was repeatedly recreated.

“Each one created their own content repeatedly, leading to duplication of effort. Whenever something changed, content had to be redone, which was inefficient,” says Pichadze.

frontline.io transformed this information into a platform that allows businesses to manage content themselves using a zero-code, drag-and-drop interface.

Converting Complex CAD Models into Usable Digital Twins

frontline.io is a cross-platform solution compatible with multiple devices and VR/AR environments.

“At the core of our technology, we have a digital twin. Any manufacturer that creates machines has huge CAD files used for assembly and planning,” Pichadze explains. “We found a way to translate that CAD file into a live digital twin — even if it has 200,000 parts — in just four minutes.”

Once converted, the digital twin is fully interactive and accessible on mobile devices, PCs, or in VR/AR, without requiring a supercomputer. Training materials and step-by-step instructions can be created directly on the model, enabling remote training without physical machines.

“You can also do on-the-job guidance, which shows technicians exactly what to do using AI and holographic procedures,” he says. “We have analytics that show exactly what the technician did and the procedure followed — giving us the full flow from design to distribution on one platform.”

“Think of us as the PowerPoint of AR and AI for industrial manufacturing.”

Ideal Sectors for frontline.io

Pichadze says the platform is suitable for any industry reliant on machinery, particularly mid-level complexity manufacturers needing to train and support global teams.

“Our main verticals are semiconductor, defence, aerospace, printing, medical devices, and heavy diesel machinery industries,” he adds.

A key advantage is its centralised app. “Our customers don’t need five or six different apps to manage everything. Typically, if you use Microsoft Remote Assist, you can’t perform job guidance or virtual training. With Frontline, you can do everything on one platform.”

The software can handle far more complex models than competitors, supporting even 200,000-part machines on mobile devices without remote streaming. It is device-independent, ensuring accessibility as hardware evolves, and incorporates AI to deliver procedures efficiently via RAG and fine-tuned XR tools.

Supporting Factory Workers and Design Engineers

frontline.io’s end-to-end platform spans multiple departments.

“Engineering designers visualise an item they design. Then the same digital twin is passed to training, which creates procedures and instructions. Operations use it for on-the-job guidance, and support teams use it for maintenance. Everyone works on the same data and workflow,” says Pichadze.

Remote support reduces costs significantly. “Instead of flying out an expert — which can take hours and cost thousands — our platform allows issues to be resolved remotely in minutes. Analytics track who did what and when, helping organisations adjust workflows and update procedures based on real-world performance.”

Reducing Downtime and Addressing Skills Shortages

A 2021 report by EngineeringUK found that 52% of young people “probably or definitely did not want to become an engineer,” contributing to a global skills shortage affecting productivity and innovation.

Pichadze believes frontline.io’s training technology can help. “It’s hard to find skilled workers, and machines are getting more complex. If there’s a shortage of training, you have to reduce training time to attract more people into the sector,” he says.

Holographic procedures and remote support make complex maintenance achievable, minimising downtime and ideally allowing predictive maintenance.

Overcoming Old Habits

Pichadze highlights that the company’s main competitor is old habits.

“Our biggest competitor is PDF and old methodologies. Especially in the hardware space, companies are more old-fashioned,” he says.

Convincing businesses to adopt XR is challenging, though early adopters like HP are experimenting with new technologies.

Future Outlook for frontline.io

The metaverse boom of recent years, which initially attracted significant investment, has declined, leading to scepticism about XR adoption.

“The initial hype and large investments that failed to scale meant many companies are now sceptical about XR,” says Pichadze. frontline.io focuses on demonstrating technology that works at scale.

The platform now serves thousands of users globally and aims to prove long-term sustainability. Pichadze envisions AI and XR becoming standard in industrial settings, including lightweight wearable devices for instant holographic procedures.

“For now, our focus is scaling globally. We’re moving our headquarters to the US and designing the next generation of technicians and maintenance training,” he concludes.